VIEWPOINT 2023: Joe Booth, CEO, Altus

Joseph Booth • 28 April 2023

Circuitnet Interview

How was business in 2022 and what do you expect for the industry in 2023?

Last year every region installed more units than ever before. This is partly driven by the broader portfolio strength and the fantastic performance of many of our new top-tier suppliers.

In 2022 we focused on high quality pre-sales and post-sales support for customers, as they have a significant influence on customer's journey. We understand that investment in their growth makes a difference. This is why we appointed a number of skilled personnel for both the pre and post-sales teams to ensure customer success. This included appointing a new UK and Ireland Operations Director who has leveraged all of his prior knowledge and experience to offer the highest standards and oversee all after-sales operational elements of the business’s strategy to lead Altus on its impressive growth trajectory.

Another area that has put Altus on top is our ability to act as a sound board and support samples validation, demos and trials to establish which solution would best fit a company's needs and budget. This value add we provide, has not only assisted customers in their investment confidence, but has allowed us to certify our equipment in real-world terms.

By focusing on how much value we could deliver on every aspect of customer interaction, we have built higher customer satisfaction, trusted ongoing support and retention.

Seeing the progression of Ireland for Altus has been one our biggest success stories not just in 2022, but in the company’s history. It is an area that I am most proud, and we have only just begun.

Due to our determination and investment in the region, we have been rewarded with repeat business, and new projects from significant accounts that have never worked with us before and who needed that level of local support when choosing a partner.

I think the outlook for the electronics industry in 2023 is pretty healthy and market conditions will be more manageable. An influence of growth is the near-shoring and re-shoring of production to the UK. This has created regional supply chains and reduced the logistics burden.

Government policy to support manufacturing and Brexit have also had an effect, with many of our partners seeing this as a chance to grasp the opportunity that comes with the changes rather than be victim to them.

Due to the super deduction and tax relief for those investing in capital equipment, the UK Government is helping companies to increase manufacturing GDP and supporting sites to become more profitable with investment incentives.

Although supply chain issues are starting to improve, CEMs still need orders from their end customers further into the future to secure component parts for production. This in turn gives CEMs a clearer picture of future cash flows, meaning that they can finance more equipment now than when their order book was less determined.

Because of this change Altus supplied equipment in 2022 to alleviate traceability issues around supply chain issues. I predict that this will continue in 2023.

We are forecasting more of the same growth for Altus and continued impact from the above points, but are unsure if this will be reflective of the whole market regionally. There are many unknowns and different factors that will affect business, including finding a solution and end to the war in Ukraine to tensions China, the USA and Taiwan. All of which will have a direct impact on controlling inflation and the global economy.

Will you be launching new products or services in 2023?

This year we will consolidate on the equipment in our portfolio. Our portfolio is already incredibly strong, so we plan to become masters in all areas and maximize on the opportunities we are creating.

Our suppliers do release new products regularly and we are looking forward to Productronica, when many companies launch innovative equipment for the first time.

Are you able to hire enough qualified employees? What could the industry do to develop a larger pool of skilled workers?

People are the most important asset to a company. We have invested a considerable amount of time to vet new starters and have them vet us for alignment.

Because we have invested time in growing our team, we have been incredibly fortunate with our recent hires. They are all in close alignment with our company objectives. I am proud of every single hire we have made in the last several years and now all of them are significant assets to our organisation.

We feel that we contribute a lot of value to our staff in their career development by offering in-depth training and opportunities. We believe in developing the next generation of engineers with next generation skills. Being a millennial and understanding the gulf of talent lost during the outsourcing period to Asia and Europe. I see there is a huge opportunity for British and Irish youngsters that come into our industry and have hunger and determination to take up the space left by skilled workers leaving.

It would be great to see more funding for apprenticeships and further practical courses available as an alternative route to university so that we can create more bright minds in the future.

Almost everything we use today contains electronics. Creating the next technologies that will influence the world from the UK and Ireland should be a goal that all we should push to achieve.

Has your company travel returned to pre-pandemic levels or are you still limiting travel to customer sites or industry conferences in 2023?

My biggest learning throughout this period is that time is my most valuable asset and that is the same for many. Flexible hours, work life balance, hobbies, friends and family... all have time creation in common.

Yes, it has returned more or less. Our engineers didn't stop visiting sites, but now it is even more regular and we can work with customers’ in-person which is always a preference. This is particularly true for new clients as it is very important to be at a customer site to understand their production environment.

We have all learned that our pre-covid travel was probably extreme. We have discovered that a Team's call is more time effective, and we now have a good balance between face-to-face interactions, cost and time savings saving and meeting efficiencies.

Joe Booth , CEO

Altus

Altus Group, a leading distributor of capital equipment in the UK and Ireland, has supported Cambertronics, an ambitious contract electronics manufacturer, in upgrading its SMT production with the installation of a Koh Young Solder Paste Inspection (SPI) system. Looking to further enhance first-pass yield and reduce the chances of costly rework, Cambertronics partnered with Altus to implement the advanced Koh Young KY8030-3 3D inspection solution. The KY8030-3 system features dual-projection 3D technology that eliminates shadow-related measurement errors, real-time PCB warp compensation, and delivers inspection speeds of 91.2 cm² per second. These capabilities enable precise volumetric measurements of solder paste deposits, allowing for the detection of issues such as bridging, insufficient solder, and misalignment at an early stage. Jasper Whitefield, Electronics Manufacturing at Cambertronics, said: “It is exciting to get the Koh Young unit into our facility, a significant enhancement to ensuring the highest quality output for our customers. More importantly, it allows us to keep our first-time right as high as possible, minimising time spent on rework and enabling us to focus on value-added internal activities. “In a competitive market, we strive to achieve maximum success, and making these strategic investments is crucial to reaching that goal. We had heard a lot about Koh Young beforehand and their market-leading position, so having this technology in our facility shows our intent to maintain those high standards.” Joe Booth, CEO of Altus Group, said: “We are always pleased to welcome another Koh Young user, especially one that recognises the critical role of SPI in process control. Unlike AOI, which detects defects after they occur, SPI helps address root causes, making it a vital investment. Cambertronics’ decision to select the KY8030-3 was a very astute one.” With Altus Group’s support and Koh Young’s cutting-edge technology, Cambertronics continues to enhance its quality and process control capabilities to meet the evolving demands of the electronics manufacturing industry. For further information, visit www.altusgroup.co.uk.

Altus Group, a leading distributor of electronics manufacturing equipment in the UK and Ireland, has expanded its Aftersales operation to its largest size to date with the appointment of new engineer, David Wissam, to bolster coverage across the South East of the UK. The appointment reflects the company’s continued investment in service capability as its customer base continues to grow. David brings with him a strong background in customer experience and manufacturing support. He most recently worked at Paxton Access, a well-established electronics manufacturer, giving him first-hand insight into the realities of production environments and the support expectations of electronics manufacturers. Mike Todd, Aftersales Manager at Altus Group, said: “It is great to see David joining the team and bringing his experience and energy into the business. Having come from a significant UK manufacturer, he understands customer challenges first-hand and can apply that knowledge to ensure we continue to support our customers to the highest level. We are proud of the size and experience of our pre-sales and Aftersales teams, and David’s appointment further strengthens that capability.” David Wissam said: “I am really pleased to be joining Altus and excited to begin my journey with the team. I have been a customer for many years and have always admired the company not just for its equipment portfolio, but for the strength and knowledge of its people. Altus has clear momentum, and I am looking forward to supporting both new projects and the existing customers the team works with.” David becomes the third team member to join the Aftersales department in the second half of the year, taking the team to its largest size to date. This expansion reflects Altus' focus on building engineers with experience across complete manufacturing lines, enabling more effective on-site support and practical, process-led problem solving. The Aftersales team has grown in response to sustained business development over recent years. Altus has added more than 100 customers along the South Coast in the past five years, as manufacturers increasingly look for long-term partners offering both advanced equipment portfolios and dependable service. In response, Altus has prioritised local engineering coverage to deliver faster, more resilient support while reducing inefficiencies associated with extensive national travel. www.altusgroup.co.uk.

Altus Group, a leading distributor of advanced electronics manufacturing equipment in the UK and Ireland, will return to Southern Manufacturing & Electronics from 3-5 February 2026 with a strong line-up of advanced process technologies from leading global suppliers. The exhibition remains one of the most significant events for the electronics manufacturing sector, bringing together equipment innovators, engineers and production specialists from across the industry. Altus will present a selection of systems that reflect the company’s commitment to improving quality, efficiency, and process control. Demonstrations will include Koh Young’s 3D Automated Optical Inspection (AOI) technology, which delivers exceptional precision and data-driven insight for quality assurance. YJ Links’ conveyoring will highlight the next step in intelligent line integration, while PVA’s latest conformal coating and dispensing equipment will demonstrate consistent performance across complex applications. Visitors will also be able to find out more about ASSCON’s vapour phase soldering technology, designed for high-reliability production, and see Scienscope’s newest innovation, the AXC-830 X-ray component counter, making its UK debut at the event. Completing the line-up is the Essemtec FOX 2 modular pick-and-place platform, offering the flexibility and scalability required for high-mix production environments. Joe Booth, CEO of Altus Group, said: “Southern Manufacturing remains a key date in the Altus calendar. It’s the perfect platform to engage directly with manufacturers and show how the right technology can transform production. For 2026, we’ve chosen a cross-section of solutions that address real customer challenges, from inspection accuracy and process traceability to automation and throughput.” Visitors can meet the Altus team on Stand J80 from 3–5 February 2026 at the Farnborough International Exhibition Centre. If you would like to arrange a meeting at the show, please get in touch with the Altus team in advance, or simply visit the stand to speak with a specialist during the event. www.altusgroup.co.uk.

Altus Group, a leading distributor of electronics manufacturing equipment in the UK and Ireland, has reported a rise in enquiries from manufacturers looking for guidance on specifying convection reflow ovens for SMT production lines. One of the most common early considerations is how many heating zones are required, a decision that can influence throughput, footprint and long-term process capability. As manufacturers compare available systems, Altus highlights that zone count alone does not provide a full picture of reflow performance. Differences in mechanical build between oven suppliers mean that systems with identical zone numbers can behave very differently in production. Heated length and cooling length therefore offer a more reliable indication of the usable thermal process window and achievable conveyor speed. In the Heller platforms supported by Altus, configurations range from compact systems with heated lengths of around 1.3 m in five zones and 0.4 m of cooling, through to larger platforms offering 4.49 m of heated length across 13 zones with 1.66 m of cooling. Seven, eight and nine-zone models, including the Heller 1707, 1826 and 1809, remain popular choices due to their balance of footprint, performance and investment level. Joe Booth, CEO of Altus Group said: “Reflow ovens can remain in service for two decades or more, so getting the specification right at the outset has long-term impact. Decisions around heated length, cooling capability and the operating window of the oven need to be made with a clear view of both current assemblies and those likely to be introduced later. Our focus is on helping manufacturers make well-informed decisions early in the project, so their investment supports production for many years.” Throughput expectations continue to be a major factor in oven selection. As broad guidance, a seven-zone system may support takt times in the region of 45–60 seconds, while eight- and nine-zone systems typically achieve 30–45 seconds. In certain applications, optimised nine-zone ovens can operate below 30 seconds. Altus advises that these figures depend heavily on product design and must be validated through structured profiling. To support this, the company recommends profiling representative assemblies using an external profiler such as Solderstar. Running these boards across different oven lengths and zone configurations helps establish where performance limits lie. Tools such as Solderstar’s Auto Seeker can also assist in assessing conveyor-speed headroom while maintaining the required thermal profile. Altus has additionally seen increased interest in dual-lane reflow systems, particularly for manufacturers aiming to boost capacity without expanding their footprint. A dual-lane configuration can provide double the reflow capacity with the right board-size balance, and with appropriate upstream and downstream shuttles, can be integrated into production lines originally configured for single-lane operation.

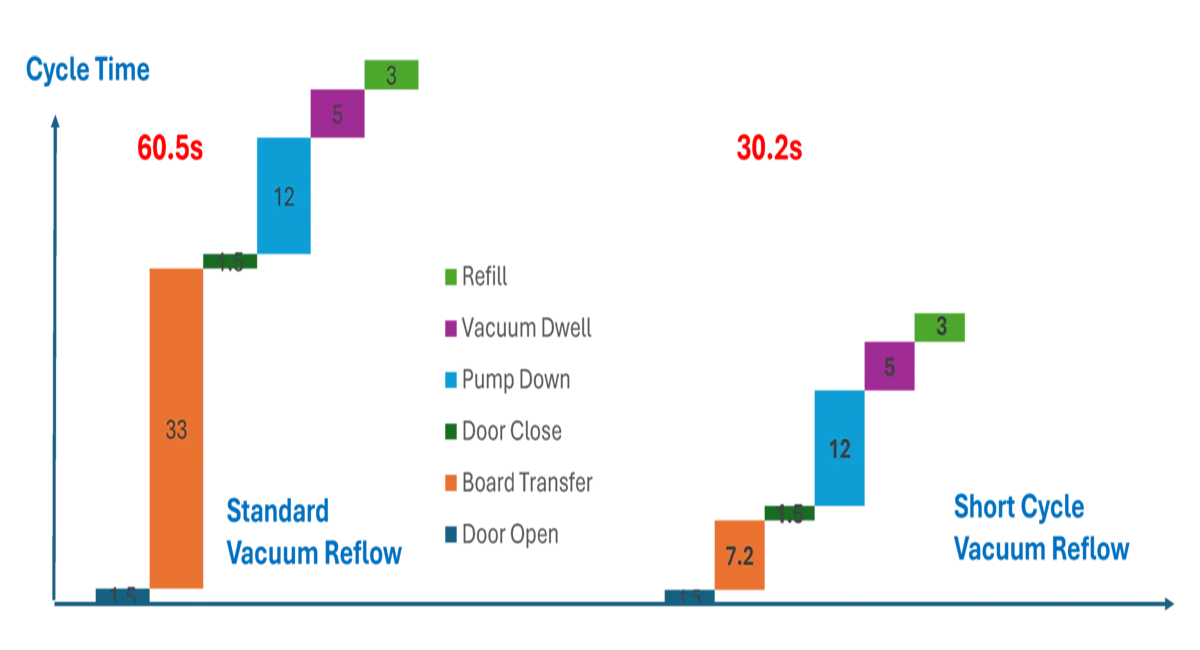

Altus Group, a leading distributor of electronics production equipment in the UK and Ireland, is highlighting Heller Industries’ innovative Short-Cycle Vacuum Reflow Oven (SCVR) as interest in high volume vacuum soldering grows across the region. Vacuum reflow soldering helps to eliminate voids in solder joints, dramatically improving reliability in demanding applications, but traditional systems have been too slow for high-volume production. Heller's SCVR introduces a patented multi-stage conveyor system that reduces board transfer time in and out of the vacuum chamber, directly addressing the primary limitation in vacuum cycle times. This innovation enables manufacturers to increase units per hour (UPH) by up to 100% while maintaining the superior solder joint reliability that vacuum reflow delivers. Joe Booth, CEO of Altus Group said: “Electronics manufacturers are increasingly looking to vacuum reflow to improve reliability in complex assemblies, but adoption has been limited by cycle time bottlenecks. The SCVR’s design makes high-volume, high-reliability production more practical than ever before, giving engineers confidence that they can meet demanding process requirements without sacrificing throughput or quality.” The SCVR features three infrared heating panels within the vacuum chamber that optimise heating profiles for solder paste. Real-time temperature control delivers ±0.5°C accuracy at the PCB level, ensuring consistent results across production runs. The system includes Heller's HELLER365 platform for process monitoring and Industry 4.0 integration, enabling real-time tracking of temperature curves, vacuum pressure values, and board-level data. The system's modular, open-architecture design simplifies upgrades, maintenance, and cleaning which is critical for maintaining uptime in high-reliability production environments. The SCVR is designed for applications where void-free solder joints are critical, including automotive power modules (IGBT/SiC packaging), RF components for telecommunications, Mini/Micro LED assembly, and high-density interconnect (HDI) soldering. By bringing Heller’s SCVR to the UK and Ireland, Altus Group continues to support electronics manufacturers with advanced assembly solutions that address both reliability and productivity demands in an increasingly competitive market. www.altusgroup.co.uk

Altus Group, a leading distributor of capital equipment for the electronics industry, has successfully supplied Concurrent Technologies Plc (Concurrent), a designer and manufacturer of mission-critical embedded computing solutions, with their second ASSCON vapour phase soldering system, the innovative VP2100-100 inline unit. Following the proven success of their ASSCON VP6000 batch system, Concurrent has invested in this latest technology to scale production capacity while maintaining the exceptional soldering quality their applications demand. The use of vapour phase technology for Concurrent is critical because it provides an inert and uniform heating environment for the most complex board requirements. This uniformity ensures quality soldering even in the face of large and heavy components alongside small and light ones which they see in many key variants they manufacture. In their specific application, this included soldering processors weighing 98 grams with 4,500 balls alongside typical SMT componentry which is incredibly challenging to do in another reflow process type. The ASSCON VP2100-100 is a high-performance inline vapour phase system designed for higher-volume applications. With its generous 750 x 620mm soldering chamber, the system can process multiple PCBs simultaneously while delivering oxygen-free heat transfer with dynamic profiling and sensor-based gradient control, ensuring reproducible process conditions that prevent overheating, component damage, or PCB delamination. Ian Gardiner, Process Engineer at Concurrent said: "We're very excited to have the new ASSCON VP2100-100 at our facility. Having previously purchased the VP6000, we were already familiar with ASSCON's capabilities and trusted their technology to meet our needs. This latest investment focuses on increasing our capacity while expanding automation within a proven vapour phase process. "Given the complexity of our products and their intricate designs, vapour phase reflow is clearly the optimal solution for achieving superior reflow performance with minimal voiding by providing uniform heat in an inert atmosphere. The VP2100's inline capability perfectly addresses our throughput requirements, providing a true inline system that eliminates the need for special carriers or manual loading operations." The VP2100-100 offers multiple PCB loading configurations with component heights up to 60mm. The system delivers 70% lower energy consumption compared to conventional reflow systems, with rapid 30-minute start-up times and full traceability capabilities, which are critical features for high-reliability applications. Joe Booth, CEO of Altus Group, said: "Concurrent is a very exciting OEM in the UK, building highly relevant products that are in strong demand. It's always rewarding when a customer invests in a repeat machine for their production facility, it signals both their business success and the proven value of the technology. “ASSCON has been a true pioneer in inline vapour phase technology for higher-volume applications, and this Concurrent installation is part of a growing number of ASSCON deployments across the UK. We're excited to see more installations planned in the coming months." For more information on ASSCON vapour phase soldering systems and Altus Group's complete range of electronics manufacturing equipment, visit www.altusgroup.co.uk.

Altus Group, a leading distributor of capital equipment in the UK and Ireland, has furthered their partnership with Sellectronics, a Contract Electronics Manufacturer, to install the PVA Delta 8 system. This strategic investment will enable Sellectronics to meet the growing demand for precise conformal coating and fluid dispensing capabilities, ensuring enhanced product protection, reliability, and compliance with stringent industry standards. The trust between Altus and Sellectronics, built across many successful prior projects, made Altus the clear partner for this important investment. Sellectronics placed significant focus on not just the machine capabilities but the local support that Altus provides—an area where they excel. With Altus now appointed as the exclusive distributor for PVA, one of the world’s leading dispensing technology providers, Sellectronics knew they were choosing both cutting-edge technology and a trusted partner to support their growth. The PVA Delta 8 system, selected for its flexibility and precision, offers a range of advanced features, including a three-axis motion platform for increased rigidity and durability, closed-loop process control for consistent quality, and support for multiple dispensing applications. The system’s servo-controlled four-axis motion allows for complex application geometries, making it ideal for the diverse needs of Sellectronics’ customer base. Jon Hurrell, Managing Director of Sellectronics, said: “The investment in the Delta 8 system is a critical step for us as we grow alongside our customers. We have high ambitions and making investments for the future will help us realise them. With Altus’ local support and the advanced capabilities of the Delta 8, we can deliver high-quality, reliable solutions while maintaining efficient and competitive operations.” Charles Lower, Sales Manager at Altus Group, added: “The strong relationship we’ve built with Sellectronics is a testament to the value we place on providing not just the best technology, but also the exceptional local support our customers need. We’re proud to continue supporting Sellectronics as they deliver cutting-edge solutions to their clients.” The installation of the Delta 8 system is part of Sellectronics’ broader strategy to enhance its capabilities and meet the evolving demands of the electronics manufacturing market. With this investment, the company is well-positioned for ongoing growth, continuing to deliver exceptional value and high-quality solutions to their diverse client base.

Altus Group, a leading distributor of capital equipment in the UK and Ireland, is introducing the LPKF CuttingMaster 2240 Cx, an advanced automated laser depaneling system designed to be fully inline, to maximise efficiency and reduce costs in high-volume PCB production. Developed by LPKF Laser and Electronics SE, the CuttingMaster 2240 Cx represents a major advancement in laser depaneling technology. The system eliminates the need for circulating workpiece carriers, simplifying automation and lowering operational costs while maintaining LPKF’s hallmark precision and reliability. Its integrated clamping device and product-specific fork handling and unloading capabilities streamline the depaneling process and reduce equipment complexity, enabling manufacturers to achieve higher throughput without additional floor space or capital investment. Joe Booth, CEO of Altus Group, said: "The CuttingMaster 2240 Cx is an impressive example of how automation continues to advance in electronics manufacturing. By removing circulating carriers and integrating intelligent handling, LPKF has developed a solution that provides both technical excellence and operational efficiency. In practical terms, it means that the CuttingMaster 2240Cx can be placed inline without the pain point of carrier handling. We are proud to support its introduction to the UK and Irish market and to help our customers adopt technology that drives productivity and process reliability. We already have customers utilising the Cx design as the initial stage of a final assembly process combined with collaborative robots." The system operates as either a standalone unit or as part of a fully integrated production line. Its LPKF CircuitPro software automatically generates optimal process data from layout files, ensuring consistent cutting quality and repeatable performance. Compatibility with robotic handling systems and standard SMEMA and OPC UA interfaces allows for easy integration with existing automation solutions, providing manufacturers with a flexible, scalable approach to production line design. Combined with a powerful laser source and advanced Tensor Technology, the CuttingMaster 2240 Cx delivers precise full contour or tab cut depaneling while maintaining a compact footprint. The system will be launched at Productronica 2025 in Munich, where it will be demonstrated as part of the Fraunhofer IZM production line. Visitors will have the opportunity to see its automated capabilities in action and understand how it addresses the growing demand for high-performance, cost-efficient depaneling solutions in the electronics manufacturing sector.

Altus Group, a leading distributor of capital equipment in the UK and Ireland, has appointed a new Applications and Service Engineer to its team, reinforcing the company’s ongoing commitment to exceptional customer support and aftersales service. Denis Popilian joins Altus from Strip Tinning Automotive, where he spent eight years as a Prototype Technician, gaining extensive experience in PCBA assembly, including SMT, THT, and robotic engineering. His technical expertise and industry experience will be leveraged to support customers across the South and Midlands, from his base in Birmingham. Mike Todd, Operations Director at Altus Group, said: "We are delighted to welcome Denis to the Altus service team. His sharp technical skills and industry experience make him an ideal addition to our growing team. “2025 has been a busy year for our aftersales operations, and with Denis joining alongside other recent additions, our capabilities are at their largest yet. This growth allows us not only to respond more efficiently to customer needs but also to be proactive in areas such as pre-sales, case management, customer training, and professional services. Denis’ expertise will help us continue raising the standard of support our customers receive.” Altus Group has strategically invested in expanding its aftersales resource pool to ensure rapid response to customer requirements, reduce downtime, and streamline service operations. By adding high-calibre technical talent like Denis, Altus is strengthening its ability to deliver both reactive and proactive solutions, maintaining its reputation for exceptional support. Denis will undergo an intensive training and familiarisation programme to fully integrate into Altus’ service operations, ensuring he can provide customers with the expertise and support expected from a market-leading service team.

Datalink Electronics has partnered with Altus Group to integrate a cutting-edge automated soldering solution, enhancing its production capabilities and reinforcing its strategic focus on quality, automation, and scalability. The partnership sees Altus providing comprehensive support for the installation of the Inertec Cube 460 selective soldering system at Datalink Electronics, a respected contract electronics manufacturer with over 40 years of industry experience serving customers ranging from multinationals to high-growth start-ups. Recognising the challenges facing UK CEMs, including rising labour costs and skilled operator shortages, Altus leveraged its technical expertise and comprehensive support network to guide Datalink through a thorough evaluation process. After assessing various selective soldering platforms and robotic options, Datalink selected Altus as their trusted partner, citing the company's strong technical capabilities and reliable support infrastructure. Under the leadership of Aran, Business Development Director at Datalink, Datalink Electronics is focused on driving automation and process improvements to meet increasing demand while maintaining quality and service standards. Altus's solution directly supports these objectives through the deployment of the Inertec Cube 460 system - a compact, modular batch selective soldering platform designed for high-mix, low-to-medium volume production. The system automates complex soldering tasks traditionally performed by skilled operators, featuring programmable soldering angles, quick-change nozzles, precise microdrop fluxing, advanced quartz pre-heating, and RT-Console software for offline programming, traceability, and real-time warpage correction. The Cube 460 supports both leaded and lead-free soldering processes, ensuring flexibility across industries. Shane Nooney, Production Engineer at Datalink Electronics, said: “What a good result! The support from both Altus and Inertec throughout this project has been excellent, and we can't fault the quality of the technical validation or the effort involved. Ultimately, the machine and its performance spoke for itself, but knowing we had a strong partner in place for after-installation support was a major factor in our decision.” Joe Booth, CEO of Altus Group, said: "I'm really pleased with this project and delighted for the team at Datalink. We've been building a trusted relationship for some time and waiting for the right opportunity, and I'm very happy with how the process went, and of course, the end result. It's great to see another Inertec 460 out in the field; we're clearly building some real momentum.” The collaboration is expected to further enhance Datalink’s process control and throughput, supporting their wider growth strategy, while reinforcing Altus's reputation as the go-to partner for advanced manufacturing solutions in the UK and Ireland electronics sector.