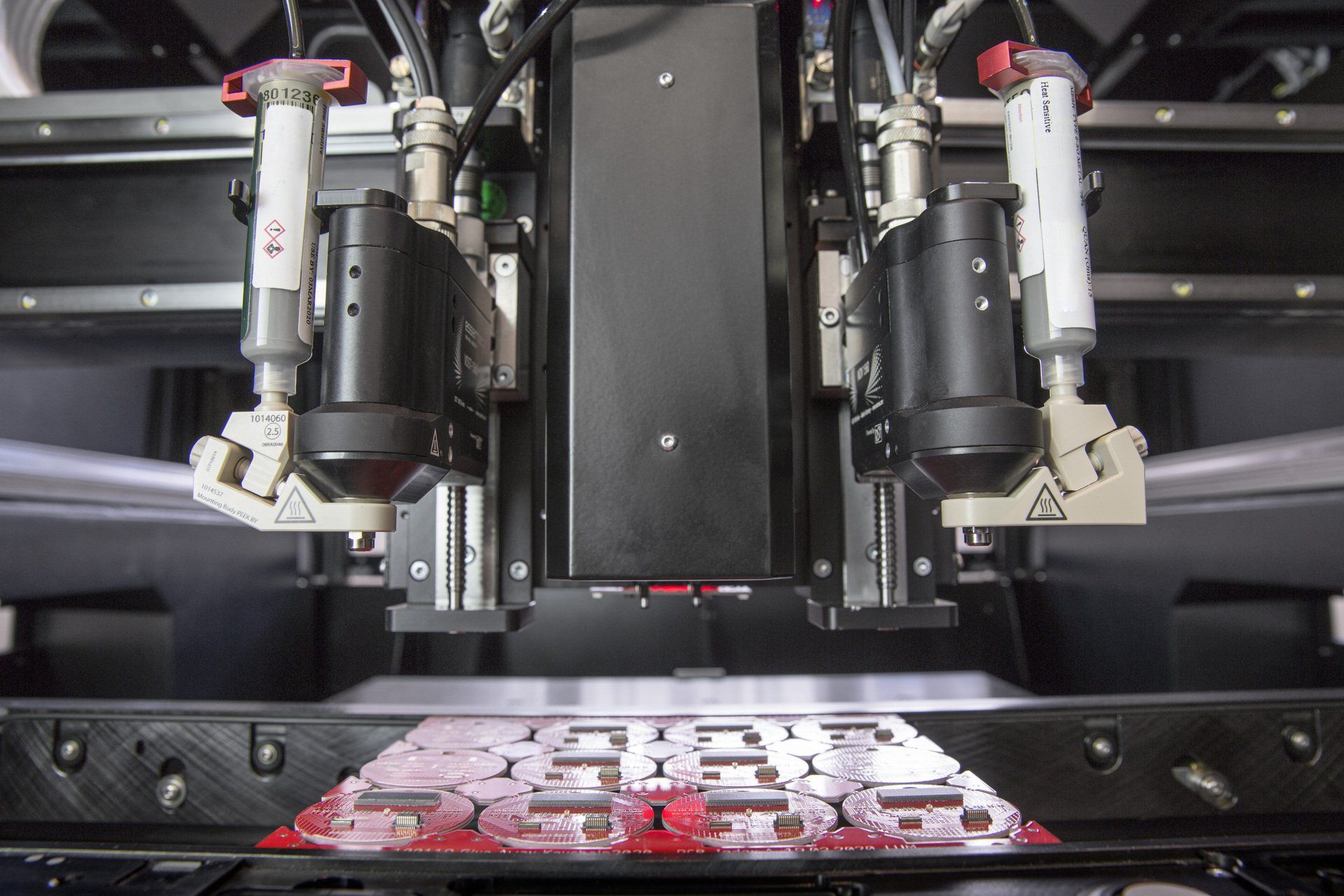

Jetting (Solder & Epoxy)

Essemtec- Dispensing

Equipped with the most modern and precise what drive and control technology has to offer today. Hardly any other medium behaves in the same way. Environmental conditions are decisive for behavior. For this reason, there are almost no standards when it comes to dosing - depending on the environmental influences and the type of liquid, there are specially tailored solutions - for every type of dosing. The simple programming and operability enables it to be used for a wide variety of dosing applications.

Flexible Modular SMT Assembly Solutions, Aimed At High Mix Low Volume Production

01

Dosing Technology

Either 2 or 3 valves simultaneously across a range of 5 valves for a broad variety of applications

02

Productivity

Up to 150,000 points an hour with piezo jet valve (solder paste)

03

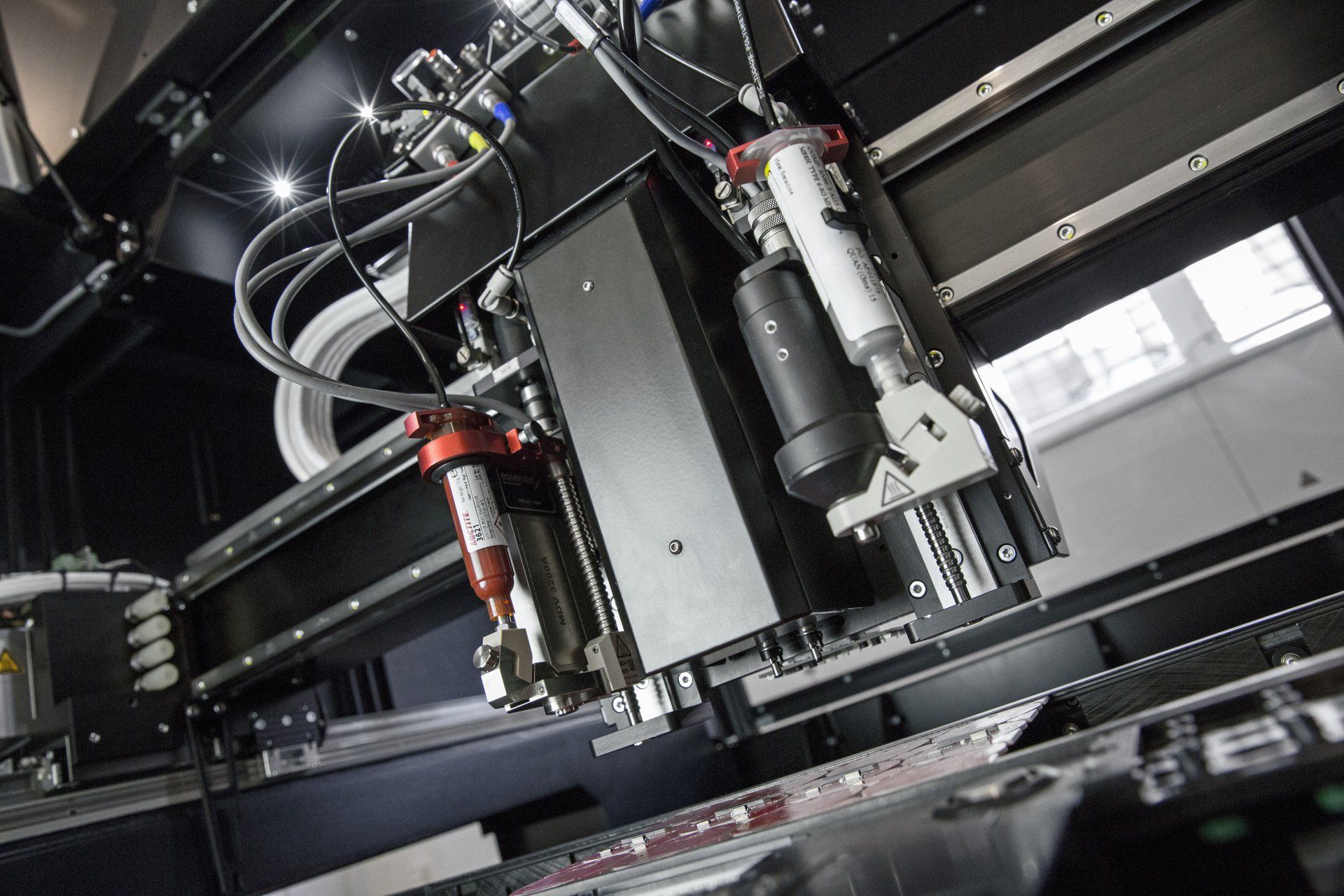

Height Measurement

Measurement of precision utilising laser technology and measurement based compensation

04

Linear Motors

Fast, double-guided linear motors. No maintenance, long service life

Dynamic shockwave

Solder paste, SMD glue

High Viscosity

Up to 260’000 dots/h

Piezo jet

SMD glue, underfill,

conductive silver glue, UV glue,

globe top, encapsulation,

solder paste

Low-High Viscosity

Up to 150’000 dots/h

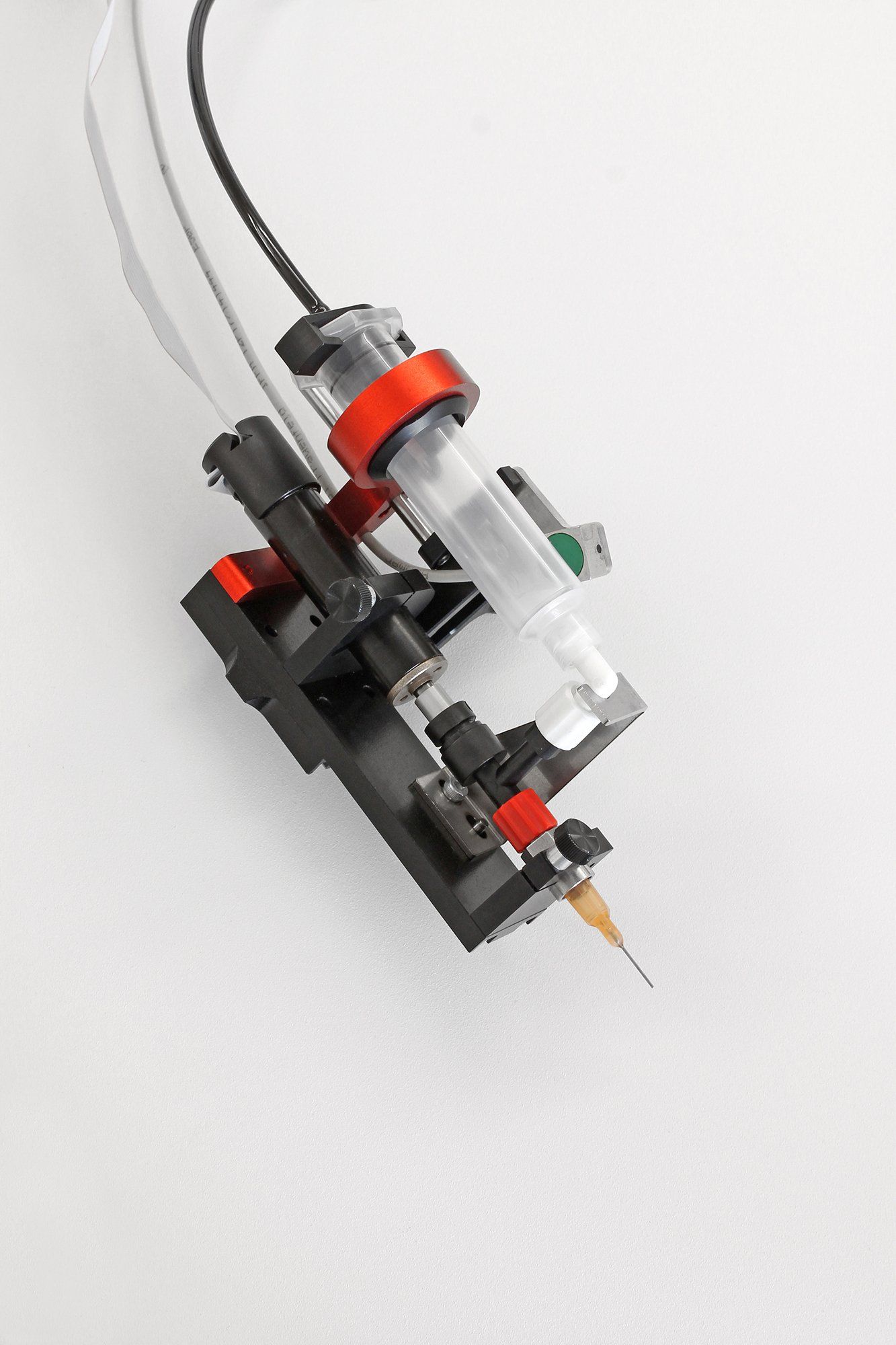

Screws

Solder paste, SMD glue,

globe top, encapsulation,

conductive silver glue , dam and fill

High Viscosity

Up to 24’000 dots/h

Time Pressure

Gasketing, globe top,

encapsulation, solder paste,

SMD glue, conductive silver glue,

dam and fill

High Viscosity

Up to 28’000 dots/h